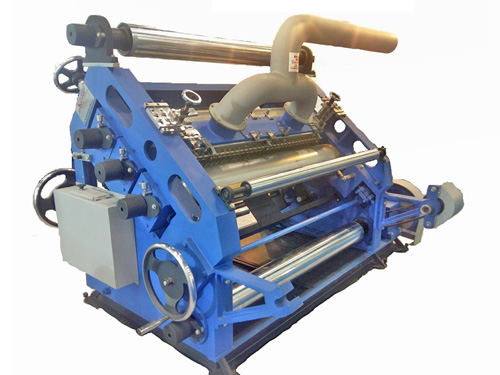

Ravi Brand Fingerless High Speed Oblique type single facer Paper Corrugating Machine (Bearing Mounted) finds place in top packaging houses around the globe due to its superior built, durability, high rate of production as well as staggeringly low maintenance costs

Ravi Brand Fingerless High Speed Oblique type single facer Paper Corrugating Machine (Bearing Mounted) finds place in top packaging houses around the globe due to its superior built, durability, high rate of production as well as staggeringly low maintenance costs

Oblique type High Speed model offers a high rate of production on the roller bearing for smooth running and longer life. The machine is fitted with gear box which runs in oil bath. The machine is provided with hydraulic self loading twin shaft reel stand and 2 pre heating cylinders. Variable speed dive and slithering blades are optional with the machine

| Size | 42” | 52” | 62” | 66” | 72" | 75" | 80" |

| Power (HP) | 9.5 | 9.5 | 9.5 | 12 | 13 | 13 | 13 |

| Power for Blower (HP) | 7.5 | 7.5 | 10 | 10 | 15 | 15 | 15 |

| Speed (m/min) | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

| Heating load (kw) | 40 | 42 | 42 | 45 | 48 | 48 | 48 |

| Pre-Heater Load (KW) | 6 | 6 | 8 | 8 | 10 | 10 | 10 |

The Oblique Type Fingerless Corrugation Machine is an integral part of the corrugated cardboard production line. It is designed to create the characteristic wave-like pattern, known as corrugation, that gives cardboard its strength and resilience. This machine is a vital component in the packaging industry, enabling the efficient and precise production of corrugated cardboard for various packaging needs.

The machine comprises several essential components, each playing a specific role in the corrugation process:

Cooling and Drying System: After the application of glue, the single-faced web passes through a cooling section to help the adhesive dry and set properly.

Cutting Mechanism: The rotary shear cuts the single-faced web to the required size.

The operational process of the Oblique Type Fingerless Corrugation Machine involves the following steps:

The Oblique Type Fingerless Corrugation Machine is used in various industries for the production of corrugated cardboard, which is then used in packaging applications such as:

The Oblique Type Fingerless Corrugation Machine is a critical component in the production of corrugated cardboard. Its efficient, high-speed operation, along with its precision and reliability, makes it an indispensable asset in the packaging industry. By following proper maintenance and safety measures, this machine ensures continuous and reliable production of high-quality corrugated cardboard for various packaging needs.

We are a leading manufacturer of Corrugation Plant Machinery, offering a range of specialized equipment tailored to optimize Corrugated Board Production. Our lineup includes

and more. With precision engineering and advanced features, our machinery enhances productivity, flexibility, and quality in the packaging industry.